In the pharmaceutical sector, filtration while adhering to quality is crucial. These entities must adhere to stringent regulations and well-defined manufacturing practices, and any lapse in quality can lead to serious outcomes. Their work environments are often sterile, and filtration is pivotal in ensuring product safety and quality. They deploy many filtration solutions, and sintered PTFE filters are usually chosen.

The Nuances of Sintered PTFE Filters

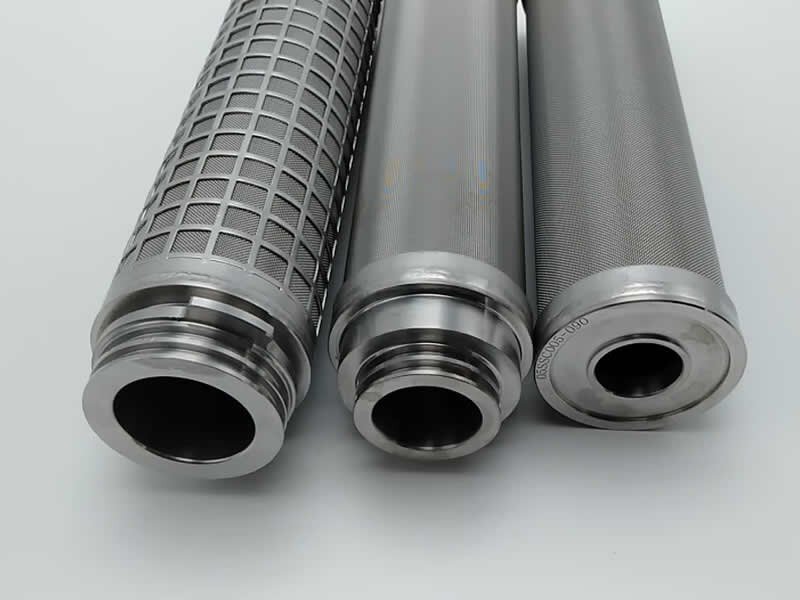

A high-performance polymer, polytetrafluoroethylene (PTFE), has excellent chemical resistance and remarkable high-temperature stability. The "sintering" process ensures the formation of a porous material with a uniform structure. The mechanical strength and resistance to strong chemicals are top-notch.

Why Is Using Sintered PTFE Filters So Widespread in the Pharmaceutical Sector?

Pharmaceutical companies use sintered PTFE filters in their workflow for various reasons. They are:

- Sterile filtration- In any pharmaceutical setup, sterile filtration is crucial. Even a tiny amount of contamination can seriously affect patient safety and drug efficacy. Top-notch sintered PTFE filters are capable of offering excellent sterile filtration. They are used for drug purification, sterilizing liquid solutions, and making aerosol-inhaled drugs. Top-grade sintered PTFE filters ensure pharmaceutical products obtain 99.99% sterility.

- Precise distribution—Sintered PTFE filters are tailor-made to comply with narrow pore size distribution. Pharma companies can opt for such filters with pore sizes as small as 0.2 microns. This enables them to achieve précis particulate removal, which is a prerequisite for maintaining drug purity and consistency. This is especially effective for batch production of significant drugs and vaccines.

- Excellent chemical resistance- Pharmaceutical manufacturers have to deal with strong solvents and chemicals in various stages of production, for sure. In such scenarios, using traditional filters may not be very effective as those will corrode. Sintered PTFE copes well with Halogenated solvents as well as Aromatic solvents.

- Hydrophobic properties—One big advantage of using sintered PTFE filters in pharmaceutical manufacturing is their hydrophobic nature. They repel water well, which comes in handy in certain pharmaceutical applications requiring flawless liquid filtration. This can be useful in manufacturing medicinal alcohol-based products and for water vapor filtration needs. The ability to filter without the risk of water vapor clogging makes sintered PTFE highly suitable for liquid filtration.

- Biocompatibility— A sintered filter made of PTFE is ideal for ensuring biocompatibility., which is why they are used extensively in medical devices. Their presence ensures the filtration is sterile and that harmful substances are not leached into the end product. This property makes sintered PTFE filters perfect for use in implants and injectables.

What About the Cost-Effectiveness?

Procuring and setting up sintered PTFE filters may not be cheap compared to alternative filter materials. However, pharmaceutical setups should look beyond the initial high setup cost. The low maintenance, great lifespan, and exceptional durability make them cost-effective.

Final Words

Using sintered PTFE filters can be beneficial for pharmaceutical sector entities. However, they must acquire such filtration products from leading PM part manufacturers in the city. They must also learn their precise filtration needs and procure filters that match those requirements well enough.

Online Clock

Online Clock